We proudly present our Project of the month:

Project of the month November 2018:

Laboratory line for the production of TPE profiles

The task:

- Extrusion line with a limited space requirement for vertical and horizontal extrusion

- Mobile execution of the units

The solution:

Extrusion line consisting of the following components:

- Mobile single screw extruder MEB 20/5x25D with flexible extruder controller

- ME Control 20/4 for output capacities up to 5 kg/h

- Manual height adjustment ± 100 mm via threaded spindle

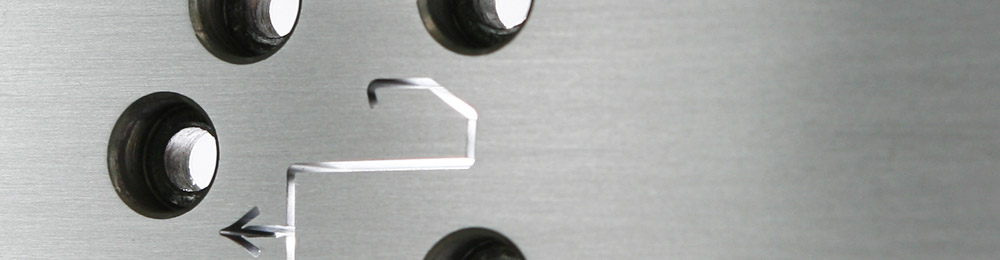

- Die system with clamping flange

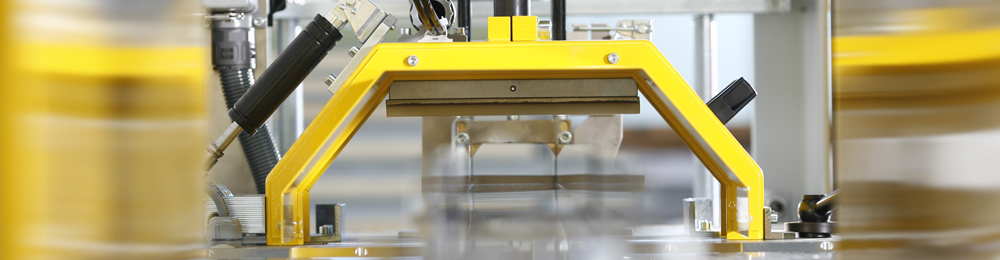

- Mobile roller haul-off for haul-off speeds from 0.3 to 6.0 m/min

- Hinged safety cover made of PC

- Manual gap adjustment of the two rubber rollers

|

|

| Die connection with tension chain | Free positioning extruder controller ME Control 20/4 |

|

|

| Roller haul-off | Roller haul-off –safety cover open |

Project Archive

Project of the month October 2018:

Complete line to produce droplet eliminator profiles made of PP TV 20

The task:

Complete line with melt pump for two die systems Laser

marking of the product inline Special saw for diagonal cuts

The solution:

Extrusion line consisting of the following components: ME

75/5x30D with mini ME Control/4, screw with barrier part

designed to process 300 kg/h Melt pump with manual screen

changer Tooling system consisting of extrusion die, dry/wet

calibration with waterbath, designed to run a production

speed of 6m/min Calibration unit ME 14/6. 2 with 3

frequency-controlled vacuum pumps Laser printing station

Haul-off unit ME 30/6.

Project of the month September 2018:

Combined saw - guillotine unit to cut different types of PVC, ABS, PP, PE, and TPE profiles

Upstroke saw ME 50/6. 1 with guillotine cutting head G1.

Project of the month August 2018:

Summer 2018 average daytime temperature:

32°C

Enten Sommer

The task:

Remain creative nevertheless

The solution:

Enten Winter

Just imagine it’s winter.

Project of the month July 2018:

Combined punching and milling unit for inline prefabrication

Punching and milling unit based on ME 41/6. 1

The task:

Introduction of position-specific punching and lateral

sectioning of profiles.

Project of the month June 2018:

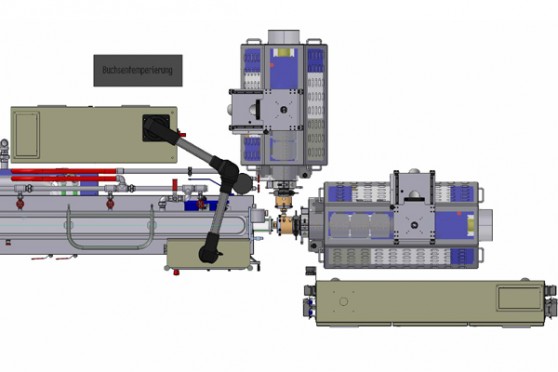

Complete coextrusion line for the production of medical tubes

Overview ME 30/5x25D + ME20x25D in coextrusion version with

downstream

The task:

Extrusion line for use in a clean room consisting of three

single-screw extruders, one calibration unit, online

measuring and testing equipment and a haul-off / cutting

unit for the production of over one hundred different mono-

and coextruded tubes made from 26 different thermoplastic

materials. The solution:

1.

Project of the month May 2018:

Extrusion line in customized design for the production of small technical profiles

Overall view ME 45/5x25D with a quick-change plasticizing

unit

The task:

Extrusion line with a quick-change plasticizing unit, a

calibration unit and a haul-off and cutting unit to

manufacture profiles from various filled thermoplastic

resins

The solution:

1. ) Single-screw extruder ME 45/5x25D with exchangeable

processing unit

Steuerung mini ME Control 4 Wechsel

Plastifiziereinheit

Controller mini ME Control /4 Exchangeable processing

unit

Zylinderanflanschung Vorheizvorrichtung Wechsel

Plastifiziereinheit

Cylinder flanging Preheating device for exchangeable

processing unit Asynchronous motor 14 kW, water-cooled

Speed up to 80 rpm Quick-change processing unit with

one-piece bimetallic cylinder 2 screws for processing filled

or fiber-reinforced plastics Controller mini ME Control/4

for the operation and monitoring of the main extruder, a

coextruder and a haul-off unit ME 30/6.

Project of the month April 2018:

Single extrusion machines in customized design for the production of technical profiles

Overall view ME 90/5x25D

The task:

Single screw extruder with melt pump, calibration unit in

customer-specific design, haul-off unit for U-profiles up to

w x h 500 x 250 mm

The solution:

1. Single scre extruder ME 90/5x25D

Steuerung ME Control 3 Zylinderheizzone isolierte

Keramikheizkoerper

Controller ME Control/3 Cylinder heating zone, insulated

ceramic heating elements Asynchronous motor 53 kW Speed

up to 49 rpm One-piece bimetallic cylinder Controller ME

Control/3 for the operation and monitoring of the main

extruder, the melt pump, a coextruder, the calibration unit

ME 14/6.

Project of the month March 2018:

Punching unit for floor panel profiles

The task:

Punching unit to prefabricate both sides of floor panel

profiles up to a width of 591 mm. The solution:

Special execution punch with two mutually adjustable

longitudinal and transverse punching heads on the basis of a

punching unit ME 4.

Project of the month February 2018:

Downstream machines for large cable ducts

The task:

Downstream extrusion line to manufacture large cable ducts

up to 620 x 110 mm consisting of a haul-off unit, a punching

unit and a saw unit

The solution:

Customized design of an downstream extrusion line consisting

of a haul-off unit ME 3, a punching unit ME 4 and a

cross-stroke saw unit ME 55. Haul-off unit ME 3

IDE Abzugseinheit ME3 Hochgezogene Transportkette ME3

Overall view ME 3 Elevated lower transport chain ME 3

Caterpillar clamping: pneumatic Drive: 2 AC motors, each

3.