Project of the month February 2018: Downstream machines for large cable ducts

The task:

-

Downstream extrusion line to manufacture large cable ducts up to 620 x 110 mm consisting of a haul-off unit, a punching unit and a saw unit

The solution:

-

Customized design of an downstream extrusion line consisting of a haul-off unit ME 3, a punching unit ME 4 and a cross-stroke saw unit ME 55.

Haul-off unit ME 3

|

|

| Overall view ME 3 | Elevated lower transport chain ME 3 |

- Caterpillar clamping: pneumatic

- Drive: 2 AC motors, each 3.8 kW

- Contact length: 2000 mm

- Pulling force: max.15000 N

- Haul-off speed: 0.5 to 10.0 m / min

- Elevated lower transport chain

- Profile clearance: 650 x 150 mm

- Controller: ME Control 20/4

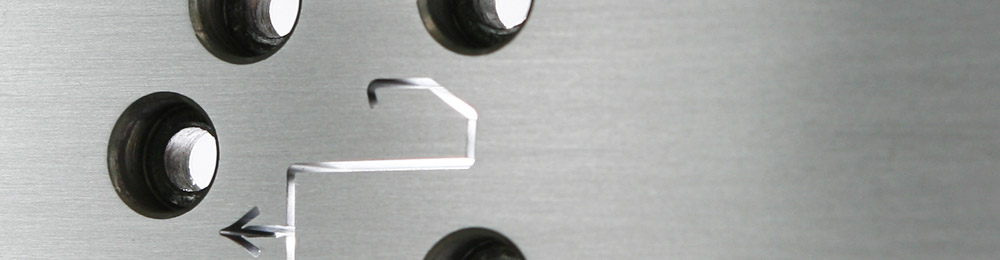

Punching unit ME 4

|

|

| Overall view ME 4 | Punching die assembly ME 4 |

- Working principle: hydraulic

- Punching force: 140,000 N at 250 bar

- Punching stroke: 20 mm

- Punching sequence: 10 strokes / min

- Concurrent travel distance: 400 mm, motorized

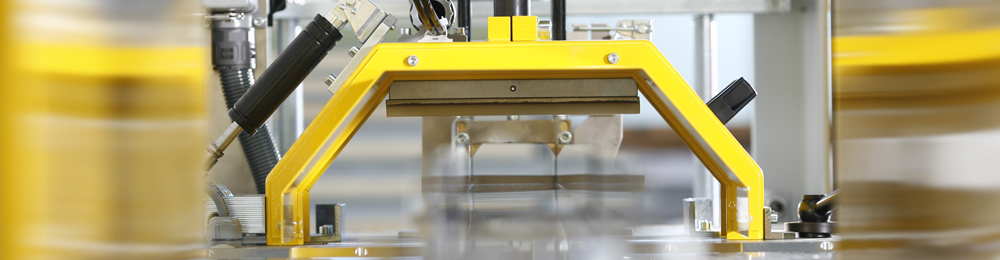

Cross-stroke saw unit ME 55

|

|

| Overall view ME 55 | Clamping bridge ME 55 |

- Saw stroke: pneumatic (vertical), motorized (horizontal)

- Concurrent travel distance: 750 mm, motorized

- Saw blade drive: 1.85 kW

- Profile clearance: 620 x 110 mm

- Controller: ME Control 20/2-K