26 October 2018

Industrie 4.0 versus data protection this was the motto of a successful In-house exhibition at IDE

Numerous customers, interested parties and business associates were inspired by the theme of this year’s in-house exhibition „INDUSTRIE 4.0 VERSUS DATA PROTECTION“

After an initial welcome and words of introduction by Mr. Alexander Ide, Mr. Thomas Ide provided an overview of the current status of the discussion regarding Industrie 4.0. He explained the challenges this poses for profile extrusion, also from the point of view of data security.

A special guest speaker was Mr. Thorsten Kühmann – Managing Director of the VDMA Plastics and Rubber Machinery Association. He expanded upon the subject of data security and concluded that: „Data security can be guaranteed if the systems are up-to-date, the data is encrypted and measures are taken to prevent manipulation. This is possible with trusted IT service and cloud providers“.

Lectures by IDE sales staff presented special solutions for downstream machinery and the integration of ancillary equipment. In another lecture, the possibilities of process data acquisition and its central visualization and further processing were explained.

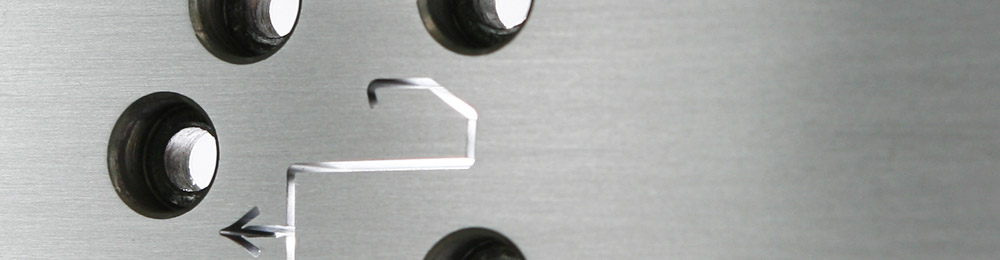

The new controller generation ME Control 20/4 is decisive for entry into Industrie 4.0. The communication protocol OPC UA (Open Platform Communications Unified Architecture) is used. This is a vendor independent protocol developed for industrial automation applications. It is based on the client-server principle and enables integrated communication from individual sensors and actuators to the ERP system or into the cloud. The protocol is platform-independent and has built-in security mechanisms.

A highlight of the lines in operation were two extrusion lines whereby process data and operating conditions were recorded while running and visualized with the help of a superordinate control system.

True to tradition, the following lines were shown in live performance:

- ME 75/5 line with melt pump and hand screen changer producing a profile from PP TV, with process data visualization and storage, as well as profile marking by laser.

- ME 60/5 line producing a profile from PA 6.6 GF 25, with inline profile measurement and determination and visualization of the energy data (vacuum, water, electricity, material throughput, etc.).

- ME 45/5 line producing a tube from transparent PVC-U, with diameter and wall thickness measurement.

All visitors could assure themselves that they have a reliable, innovative partner who puts their needs first.