We proudly present our Project of the month:

Project of the month January 2018:

Single-screw venting extruder

The task:

Single-screw extruder for processing PMMA / PC with a venting unit, screen changer and melt pump.

The solution:

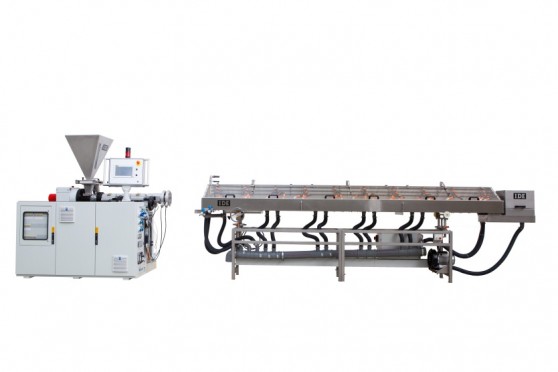

Single-screw extruder ME 38/5x33D-E for processing PMMA and PC and designed for continuous operation temperatures up to 350°C.

|

|

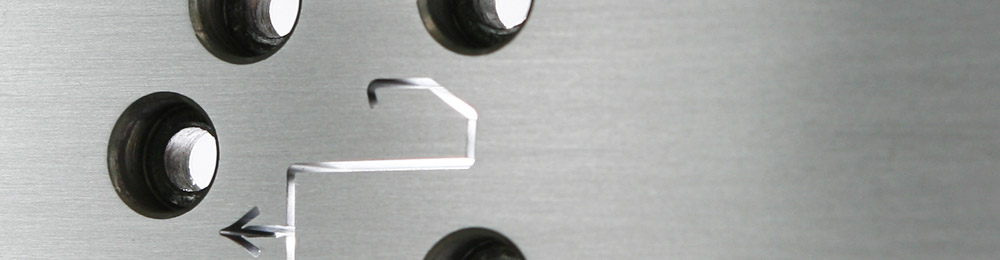

| Cylinder venting | Hopper displacement device |

Single-screw extruder ME 38/5x33D-E

- Asynchronous motor 4.3 kW, water-cooled, speed up to 70 rpm

- Special screw, plasma-nitrided for processing PMMA

- Melt pressure and melt temperature measurement; Hopper volume 12 litres

- Extruder control mini ME Control /4; TFT colour screen

- (10.1” touchscreen); Synchronous operation for pump, extruder and haul-off

- Smooth-bore cylinder, bimetal

- Energy-efficient heating / cooling combination with ceramic heaters, integrated insulation and convection flap system

- Melt pump, throughput PMMA/PC approx. 20 kg/h, control, monitoring and pump pre-pressure regulation integrated in mini ME Control/4

- Venting unit, vacuum pump, galvanized separating tank

- Manual screen changer, discontinuous

|

|

| Manual screen changer | Melt pump with clamping flange |

Project Archive

Project of the month December 2017:

Special extruder to manufacture PE sheets

The task:

Special extruder to produce 200 mm wide sheets from PE

The solution:

Single screw extruder ME 60/4x37D Three-phase drive 115 kW;

water-cooled, speed up to 240 rpm Barrier screw for an

output of PE granules up to 300 kg/h Two-part cylinder with

grooved feed zone; Melt pressure and temperature measurement

Extruder controller ME Control /3 with a 15” TFT colour

touchscreen. Manual screen changer with 2 screen cavities

and 2 heaters Deflection head to feed the sheet die, slot

width 200 mm and lip aperture 18 mm Dosing & mixing station

for 300 kg/h throughput; Conveyor up to 350 kg/h

Plattenduese Siebwechsler

Sheet extrusion die Screen changer

Zylinder Foerdergeraetaufbau Umlenkkopf

Cylinder with mounted conveyor

Deflection head for the sheet die.

Project of the month August 2017:

Multifunctional single screw line

The task:

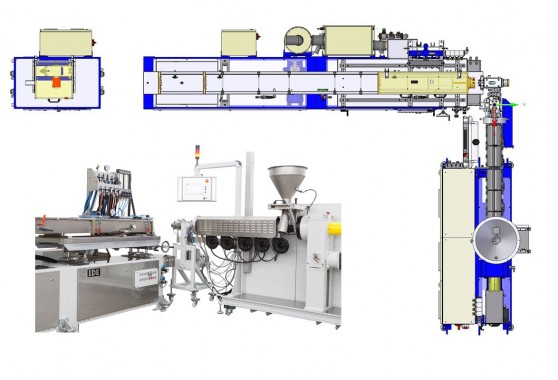

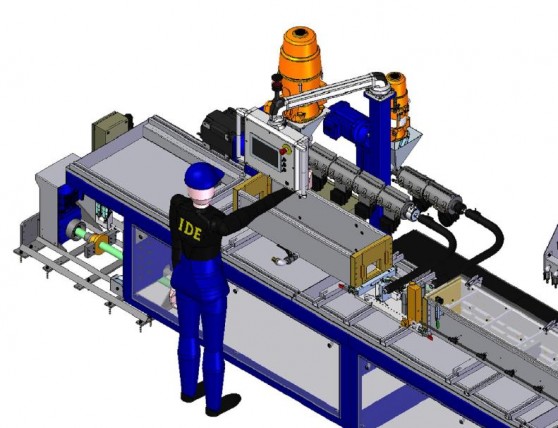

Extrusion line to process TPU for a flat profile, for

tubing, and to run a crosshead die to sheath cable strands. Standardaufstellung

Standard set-up

The solution:

Single screw extruder ME 45/5x30D to process TPU, combined

with a fusion pump.

Project of the month July 2017:

Extrusion line to produce PVC-F sealing profiles

The task:

To construct a single screw extruder with optimized output

for TPE / PVC-F To develop and construct a special spraybath

with an integrated conveyor belt fora sealing profile

The solution:

Single screw extruder ME 45/4x25D AC-drive 15 kW,

air-cooled; Screw speed 92 min-1; Integrated profile edge

control; Hopper, 3-position slide mechanism with linear

guide; Grooved feed bush; Special screw to process

TPE/PVC-F; Controller mini ME Control/4. Downstream

calibration unit in stainless steel (VA) Total length 4.

Project of the month June 2017:

Retrofit ME60/3X25D

The task:

Year of manufacture 1996, more than 20 years old, 56. 838

machine hours and still worth repairing.

Project of the month May 2017:

Post-coextrusion

The task:

Space-saving integration of two post-coextruders on a

calibration unit for the extrusion of a PVC-F soft lip and a

TPE strip onto a roller shutter guide rail. Mounting possibility for a 5m long calibration system

consisting of a vacuum tank (3m), a spray waterbath (1m) and

a post-coextrusion station (1m).

Project of the month April 2017:

High performance extruder for PP/HD-PE

The task:

Single screw extruder to process PP/HDPE with an output of

up to 400 kg/h; Integration of a manual screen changer and a

melt pump

The solution:

Single screw extruder ME 60/4x37D with a grooved entry bush

combined with a manual screen changer and a melt pump

Total length of the machine 3,750 mm

02 03

Screen changer with melt pump AC-drive 115 kW,

water-cooled Single screw extruder ME 60/4x37D

Synchronous three-phase drive 115 kW, water-cooled, speed up

to 240 rpm Special screw, nitrided for PP/HDPE outputs up to

400 kg/h Melt pressure and melt temperature measurement;

Material hopper 150 litres 6 barrel heating zones with

cooling fans; 1 flange heating zone 4 die heating zones;

Extruder control ME Control/3; TFT colour display 15”

touchscreen; Synchronization of melt pump, extruder and

haul-off Manual screen changer 2 screen cavities with 2

breaker plates; Screen diameter 123 mm; 1 heating zone with

2 heaters Melt pump integrated in the frame AC gear motor 11

kW; speed 52 – 113 rpm; Feed pressure max. 200 bar 1

heating zone with 4 heating cartridges

04 05.

Project of the month March 2017:

Laboratory extrusion line

The task:

Laboratory extrusion line to produce PVC-U test strips for

material testing

The solution:

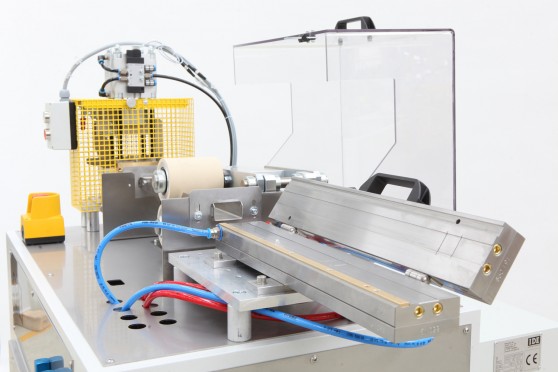

Single screw extruder ME 30/4x25D, extrusion die for flat

profiles 25x1mm, laboratory downstream line (SampleSizer)

consisting of a calibration table, a roller haul-off and a

cutting unit G1

101

Total length of the line approx. 2,800 mm

102 104

Extrusion die Guillotine

103

Roller haul-off Single screw extruder ME 30/4x25D AC

drive 4.

Project of the month February 2017:

Double Drill-Saw Unit

The task:

To integrate an interval feed unit provided by the customer

which inserts profiles into a double drill-saw unit

for finishing. To integrate the external trigger signal of the feed unit.