Project of the month May 2017:Post-coextrusion

The task:

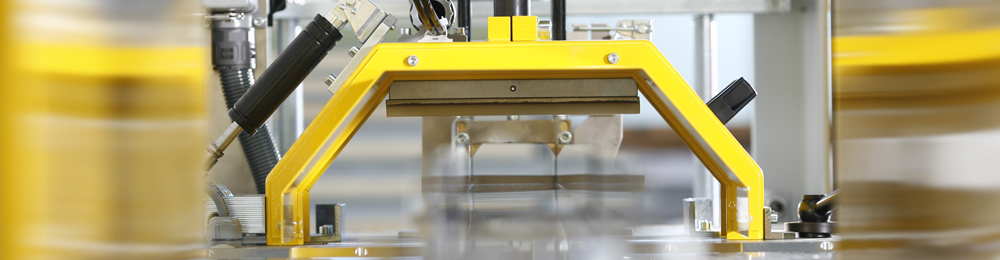

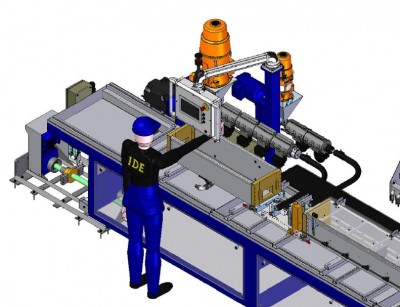

Space-saving integration of two post-coextruders on a calibration unit for the extrusion of a PVC-F soft lip and a TPE strip onto a roller shutter guide rail.

Mounting possibility for a 5m long calibration system consisting of a vacuum tank (3m), a spray waterbath (1m) and a post-coextrusion station (1m).

|

2 parallel-mounted post-coextruders: Ø 38 mm for the PVC-F soft lip Ø 20 mm for the TPE strip |

The solution:

Calibration unit ME 16/6.5:

- Extrusion height 1100 mm

- Calibration table 700x6000 mm

- Longitudinal adjustment, motorized (± 250 mm)

- Height adjustment, motorized, separate for intake and outlet sides (± 60 mm)

- Cross adjustment (± 25 mm)

- 5 vacuum pumps, each 4,3kW with quick-change connectors

- 4 manifolds, each with 10 vacuum connections ½“ and 10 water connections ½“

- 1 vacuum connection 5/4“ for the spray waterbath

Single screw coextruder MEB 38/4x25D:

- AC drive 7,1 kW with spur reduction gearbox

- Screw speed max. 67 rpm

- Nitrided barrel with water-cooled entry zone

- 4 barrel heating/cooling zones

- Hopper, vol. 6 litres, with lid for the dosing unit

- Screw to process PVC-F (4 to 20 kg/h)

- Flexible heating hose, 1,0 m

- Melt pressure and temperature measuring

Single screw coextruder MEB 20/5x25D:

- AC flat gear motor 2,6 kW

- Screw speed max. 197 rpm

- nitrided barrel with water-cooled entry zone

- 2 barrel heating/cooling zones

- Hopper, vol. 6 litres, with lid for the dosing unit

- Screw to process TPE (0,5 to 5 kg/h)

- Flexible heating hose,1,0 m

Screen controller mini ME Control /4:

- 25,6 cm (10,1“) analogue, resistive Touchscreen

- Speed setting via digital potentiometer

- Temperature control with actual value display, heating current display and alarms

- Weekly timer

- Display of the main data on all pages

- Screen-assisted operator help

- Data carrier functions with interface (USB Port)

- Trend graphics

- Recording of process variables

- Recipe management

|

|

| Vacuum system | Single screw exturder ME B 38/4x25D |