Project of the month December 2018:Complete line for the production of various filter profiles

The task:

- Downstream line for more than 6 different filter profiles with diameters of 15 – 120 mm

- Constructed mainly of rustproof materials

- Spray waterbath with individual spray bar adjustment

- Profile drying via suction technology

- Belt haul-off with constant center of extrusion

- Cutting unit for profiles up to 125mm in diameter

The solution:

Extrusion downstream line consisting of the following components:

- Calibration downstream with more than 60 spray nozzles

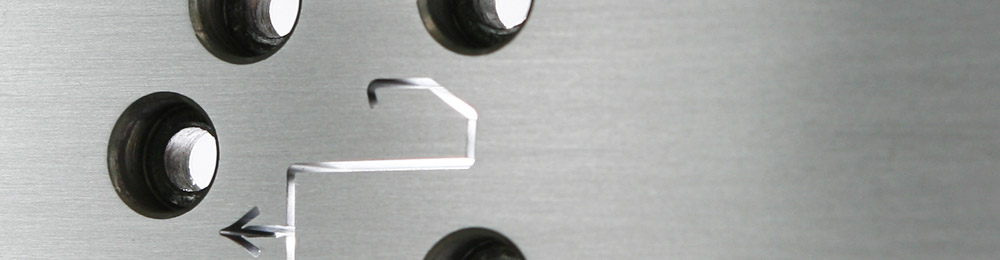

- Exchangeable spray ring at the inlet side

- Suction ring with exchangeable nozzles of different dimensions at the outlet-side

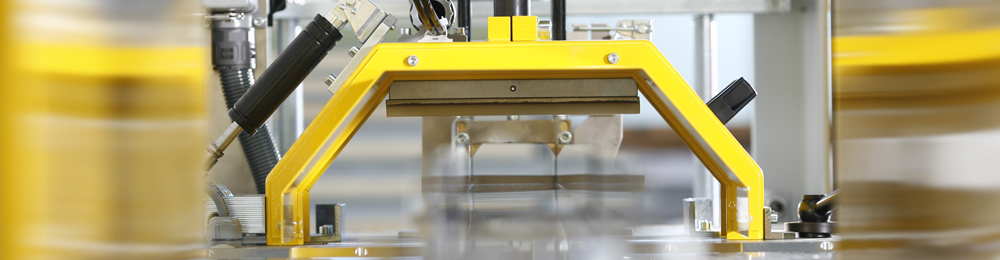

- Belt haul-off with centralized manual gap adjustment

- Rotary cutting unit for profile diameters up to 125 mm

|

|

| Spray ring at the inlet side | Spray waterbath |

|

|

| Suction technology at the outlet side | Belt haul-off with gap adjustment |

|

|

| Rotation cutting unit | Controller ME Control 20/4 |