Project of the month January 2018:Single-screw venting extruder

The task:

Single-screw extruder for processing PMMA / PC with a venting unit, screen changer and melt pump.

The solution:

Single-screw extruder ME 38/5x33D-E for processing PMMA and PC and designed for continuous operation temperatures up to 350°C.

|

|

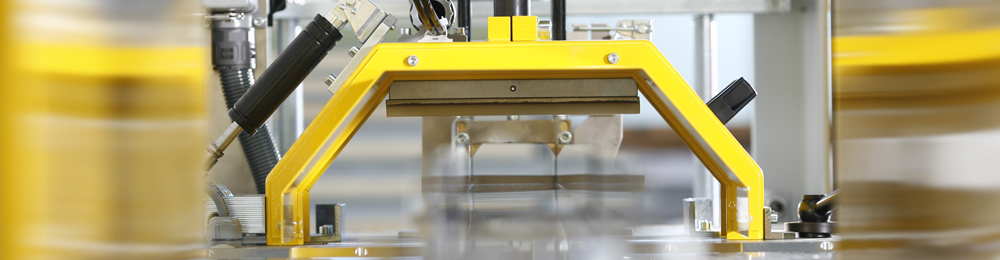

| Cylinder venting | Hopper displacement device |

Single-screw extruder ME 38/5x33D-E

- Asynchronous motor 4.3 kW, water-cooled, speed up to 70 rpm

- Special screw, plasma-nitrided for processing PMMA

- Melt pressure and melt temperature measurement; Hopper volume 12 litres

- Extruder control mini ME Control /4; TFT colour screen

- (10.1” touchscreen); Synchronous operation for pump, extruder and haul-off

- Smooth-bore cylinder, bimetal

- Energy-efficient heating / cooling combination with ceramic heaters, integrated insulation and convection flap system

- Melt pump, throughput PMMA/PC approx. 20 kg/h, control, monitoring and pump pre-pressure regulation integrated in mini ME Control/4

- Venting unit, vacuum pump, galvanized separating tank

- Manual screen changer, discontinuous

|

|

| Manual screen changer | Melt pump with clamping flange |